Bobsled Design Improved with Computer Simulation

TotalSim US Works with Bobsled Designer to Gain Speed on Track

The Situation:

Over the past several decades, the Olympics has become a more technological event. Athletes are always looking to get an edge on the competition and are using science to do it. Advanced suit technology for swimming, wind tunnel testing for cyclists, ski jumpers, skiers, and sliding sport athletes to determine the best body position and equipment upgrades are just a few of the technologies used. The bobsleigh competition in the Winter Olympics is no different; with races decided by the hundredth of a second, even small advances in technology can mean the difference between first and last. Aerodynamics play a large part of the bobsled design and is often where teams look when they are wanting a little more speed.

Client Challenge:

Developing a new bobsled is an expensive task. There are many rules and regulations regarding the bobsled design that limit the changes that are allowed and this makes it difficult to realize large improvements on any part of the bobsled. Even in the recent past, bobsled design is often done based on intuition by a designer with wealth of experience. Often design changes are implemented on different parts of the bobsled and these are tested individually with the hope that individual component drag improvements will add up when all the improved parts are put together. Wind tunnel and on track testing has been used to determine what is the best path to take but this can be costly and dangerous for several reasons. The cost of making a prototype bobsled with multiple interchangeable parts can become overwhelming for a designer especially when cost is a factor. Wind tunnel testing is more controllable but a major problem is how to represent the walls that are moving by the bobsled while on track. However, full scale wind tunnel tests become complex and more risky when adding athletes into the mix. Obviously dummies can be used but this limits what you can test.

Type of TotalSim Engagement:

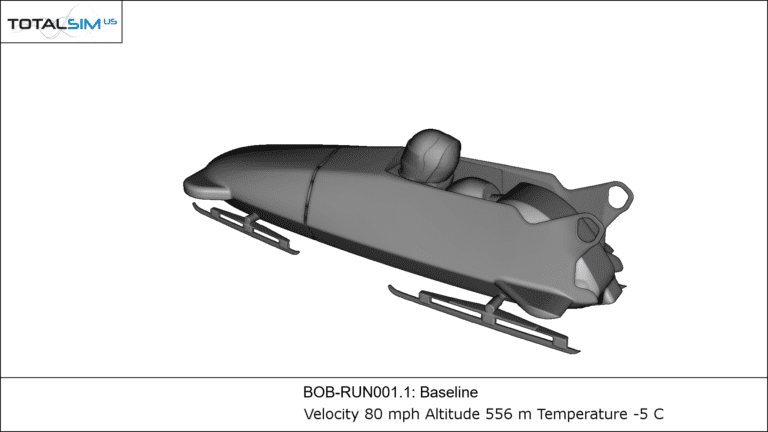

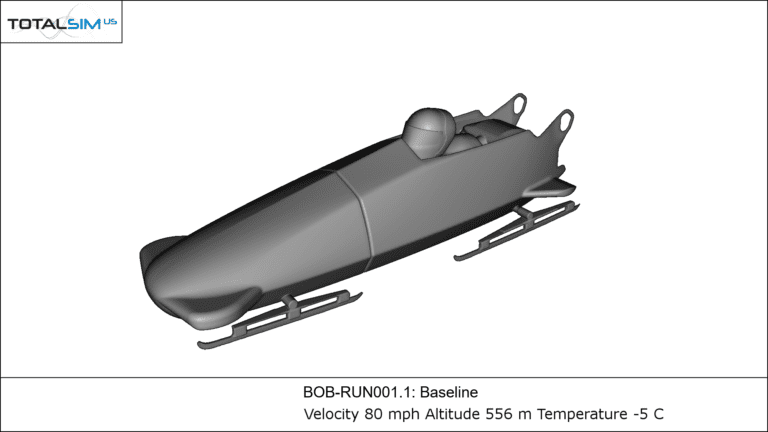

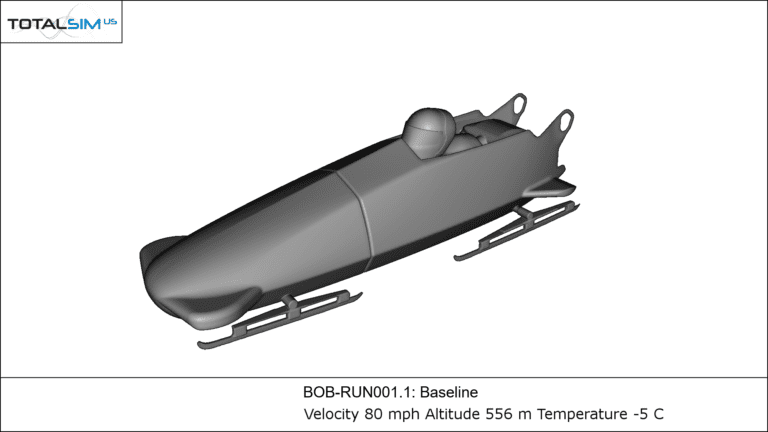

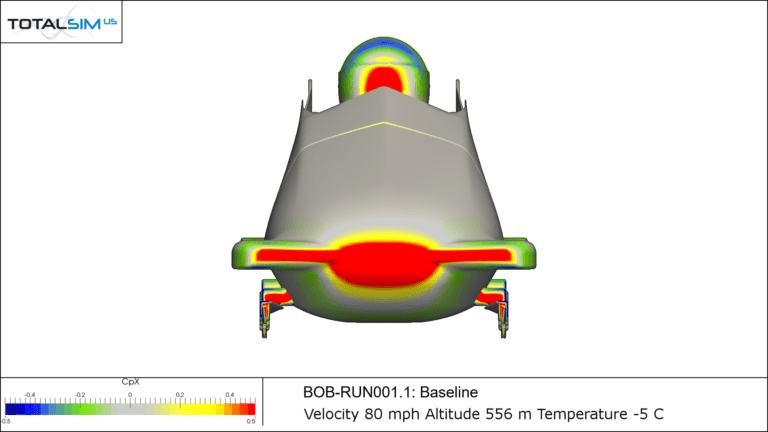

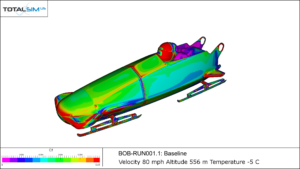

TotalSim has years of experience testing aerodynamic efficiency on bobsleds. Computational Fluid Dynamics (CFD) is an ideal way to study a bobsled design because changes can be evaluated to determine the flow mechanisms that influence all parts of the bobsled. In 2018 and then again in 2019, an independent bobsled designer contracted TotalSim to improve the aerodynamic performance of a new “clean sheet of paper” bobsled design.

What TotalSim did:

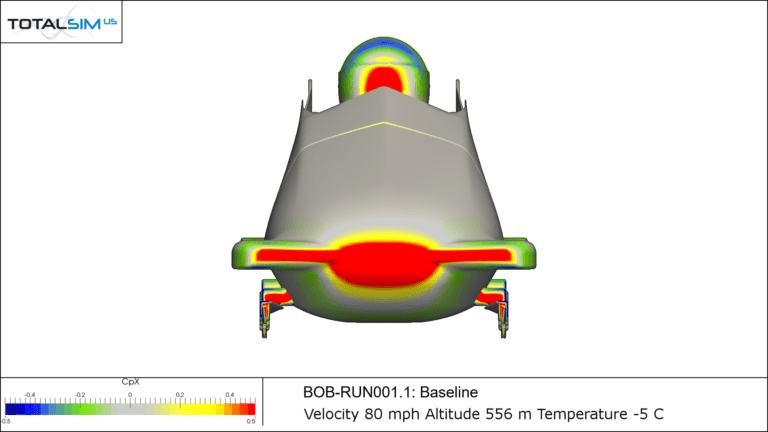

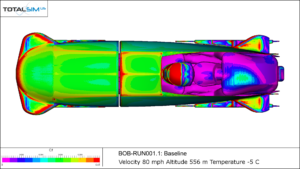

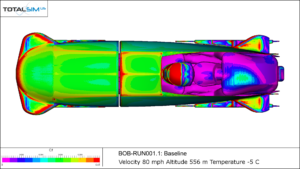

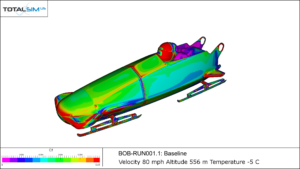

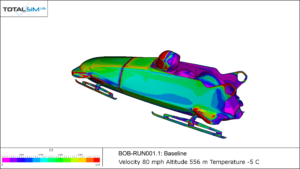

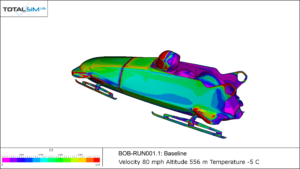

The designer and TotalSim worked closely together to develop a CFD test plan to evaluate different bobsled configurations. The plan included studying some historical designs to give a good baseline model on which to improve upon and then studying variation of individual parts including things like nose and bumper shapes and the effect of the cowling gap. The test plan even included simulations where the bobsleds were evaluated in both curved and a straight track sections in order to obtain the most accurate data. And finally, an adjoint study (a shape optimization method using surface sensitivities) was performed to improve the bobsled design in even more detail.

Results:

Each part of the bobsled was individually optimized on a baseline bobsled and then all the optimized parts were put together and tested on the final case. The extensive test plan included multiple nose shapes, front and rear cowlings and front and rear bumpers. Through our optimization and adjoint study, the final configuration showed an overall 4.4% drag improvement on curved track sections and an 8.2% improvement on straight track sections compared to the historical baseline design. When fractions of seconds separates winning from losing, this kind of improvement can make all the difference in the world.

Note

The images in this case study represent the original baseline model and do not reflect the final design for this project.

Learn more about the ways TotalSim can help you overcome your aerodynamic challenges

*What is CFD?

Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses computer numerical analysis and data structures to analyze and solve problems that involve fluid flows, typically solved on large supercomputers. Fluid mechanics plays a significant role in the engineering process when developing new designs. Analyzing the aerodynamic and thermal qualities of a product using experimentation is a well-established approach however experimentation can be costly, limiting, time-consuming, and difficult to execute especially on a large scale. Progression of computing power has allowed the field of CFD to prosper acting as a complement to physical testing and in some cases replacing it. CFD is the science of predicting fluid flow, heat transfer, mass transfer, chemical reactions, and other flow properties by solving governing fluid flow equations using numerical methods. Across the industry, CFD is routinely used to drive product development, troubleshoot issues, study and optimize new designs and concepts, and map performance. CFD methods are heavily used across many disciplines with motorsports being a leading proponent.