Getting you to market faster, lowering your costs & optimizing your designs.

Since 2009, TotalSim US has leveraged state-of-the-art CFD simulation to provide unparalleled accuracy across eleven industries.

Having completed over 1,200 projects, TotalSim’s automated workflows improve accuracy and return results faster, significantly reducing time-to-market and research and development costs for every unique goal.

Let our decades of proven computational fluid dynamics (CFD) experience work for you.

Why TotalSim?

TotalSim expertly applies advanced CFD technology accurately and efficiently to solve your most complex engineering challenges.

Guaranteed Accuracy

![]()

![]()

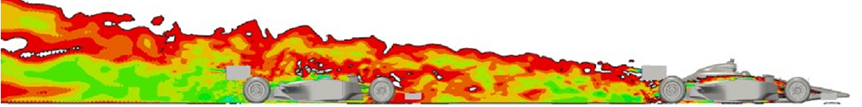

Our simulation and modeling expertise allows us to study & evaluate problems you wouldn't be able to do on your own. We provide you with more accurate data than physical testing to support your decisions, so you walk away with improved design and performance at the best value for your investment.

Increased Efficiency

![]()

![]()

By leveraging CFD outsourcing through TotalSim, you tap into our arsenal of digital engineering tools, ensuring consistently high-quality results while drastically reducing reliance on physical testing. This heightened efficiency not only trims expenses on software licenses, internal expertise, and hardware but also optimizes your workforce utilization.

Reduced Cost

![]()

![]()

Partnering with TotalSim to tackle your CFD challenges means bidding farewell to months spent mastering costly software utilized sporadically throughout the year. Entrusting us with your project minimizes the necessity for staff training while granting you immediate access to our top-tier services and significantly reducing project costs.

Siemens Software Partner

TotalSim proudly announces its partnership with Siemens Digital Industries Software, becoming an official reseller of STAR-CCM+ software. STAR-CCM+ is a top-tier CFD solution used across diverse industries for simulating fluid dynamics, heat transfer and multiphysics phenomena. This comprehensive suite empowers engineers and researchers to analyze designs and predict performance in sectors like automotive, aerospace, energy, and marine. Leveraging over 20 years of experience with STAR-CCM+, TotalSim offers unmatched expertise and support to clients, ensuring efficient innovation and cost savings.

Trusted by Engineers Everywhere

What is CFD?

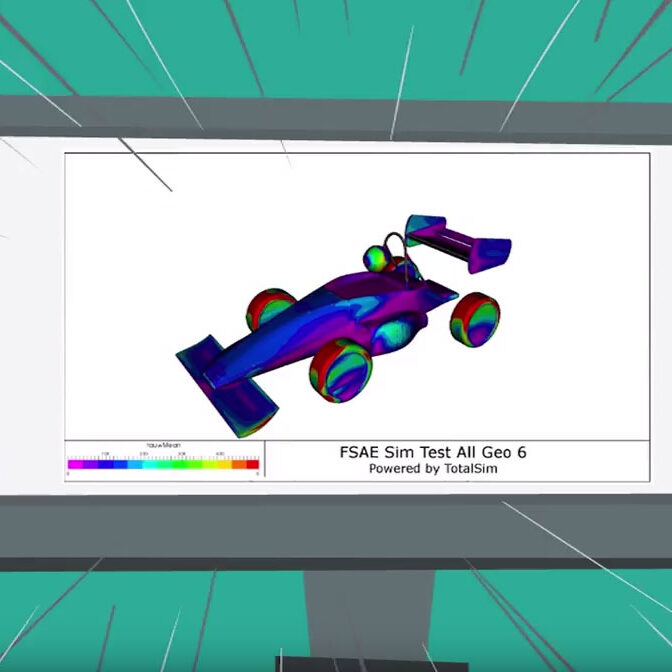

Computational fluid dynamics (CFD) is a branch of fluid mechanics that utilizes numerical analysis to digitally predict fluid flow. Fluid mechanics plays a significant role in the engineering and design process. Analyzing aerodynamic and thermal performance of a product using an experimental process can be costly, limiting, time-consuming and difficult to execute on a large scale. Computing power has allowed the field of CFD to act as a complement to physical testing and in some cases, replacing it. CFD allows engineers to predict fluid flow, heat transfer, mass transfer, chemical reactions and other flow properties by solving governing fluid flow equations. It is widely used across all industries.

News Feed

Keep up with the latest news and information from TotalSim – from new service offerings and industry apps, to company updates and more.