Using CFD to Evaluate Medication Delivery

TotalSim US Evaluates Medical Device

The Situation:

Patients need to be put on a ventilator for many reasons including while under general anesthesia during surgery or respiratory distress. Some patients will have problems that result in constriction of bronchi and bronchioles which needs to be treated by administering bronchodilators such as Albuterol and Ipratropium. While the medications are readily available, the most common method for administering these medications is using a metered dose inhaler (MDI). Using a MDI on a patient who has an endotracheal tube (ETT) inserted is cumbersome and time-consuming and the method often results in a dosage that is not sufficient to achieve the desired results. Better delivery and quantification of the amount of medication delivered deep into the lungs is needed.

Client Challenge:

A medical device startup company developed a device to better deliver bronchodilators to patients who are intubated. They needed a way to prove their concept, quantify the amount of medication delivered, and determine how far medication is delivered into the lungs. The company didn’t have the ability to do this type of analysis and needed to find a partner capable of conducting a fluid and particle flow analysis.

Type of TotalSim Engagement:

TotalSim US was approached by this startup with a request to conduct a Computational Fluid Dynamics (CFD*) study of their new device. It was necessary to have a study that tracks particles (representing the medication) in the air flow to determine where and how far the particles travel into the lungs. TotalSim worked with them to evaluate the current method of drug delivery and then compare that to the new device developed by the company using CFD analysis.

What TotalSim did:

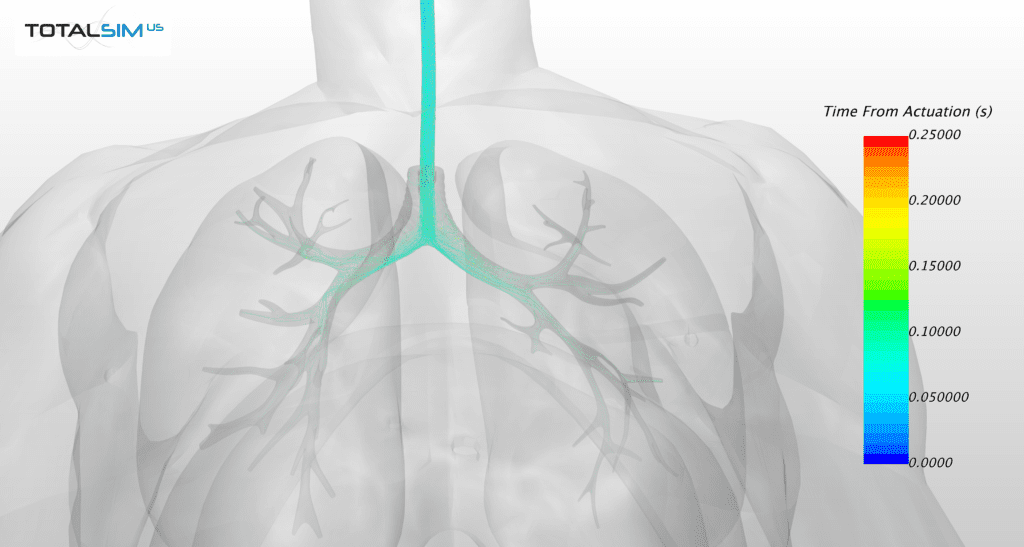

Instead of only modeling the ETT to determine the amount of medication that is delivered to the end of the tube, TotalSim created a more complete model that included a bronchial tree beyond the endotracheal tube so that measurements could be made of how far and how much medication was deposited into the bronchial tree. This way the test would more completely simulate the conditions under which the medication was delivered.

A baseline case was created that mimics the current standard practice for administration of bronchodilators while a patient is intubated. This method requires a detachment of the ETT from the ventilator and the MDI is used to insert medication into the end of the tubing and the ventilator is reconnected. The volume of flow from the MDI was used for the initial conditions to generate the flow field. TotalSim was provided with data from experimental studies of this method of delivery that would allow for correlation of the simulation data.

The second case included the new device designed by the medical device company and uses a connector to attach the MDI to the ventilator circuit eliminating the need to disconnect the EET from the ventilator when administering the medication. They theorized that this method would deliver more medication farther into the lungs because the flow from the ventilator assists in delivering the medication. TotalSim updated the geometry to include the new device in the ventilator circuit and updated the flow settings to include the connected MDI and ventilator flow conditions. With these updates the new simulation was conducted.

TotalSim commonly does this type of baseline versus baseline-with-changes for clients as it is the basis for any incremental design process.

Results:

As previously mentioned the first step in a program like this is to correlate a baseline case to experimental data when available. After some testing, it was determined that a transient CFD simulation generated results that most accurately corresponded with the baseline experimental data; therefore, transient simulation was carried out for the rest of the project. Experimental data is not always available but this kind of correlation gives confidence that derivative studies will accurately represent the system being evaluated.

After the baseline correlation was complete, then the newly developed device was incorporated into the model as described above. This movie shows the flow of the particles into the bronchial tree for the second case. These results showed a slight improvement over the baseline case.

This image shows streamlines of the particles into the bronchial tree.

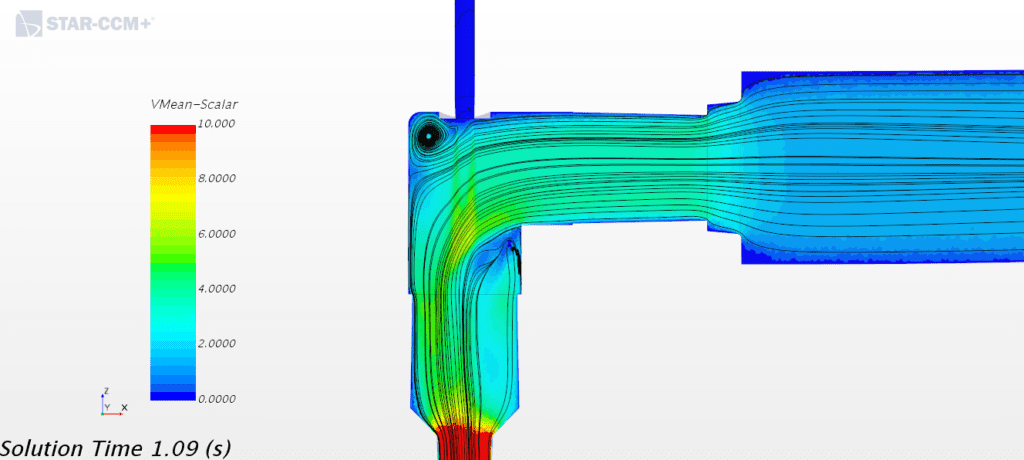

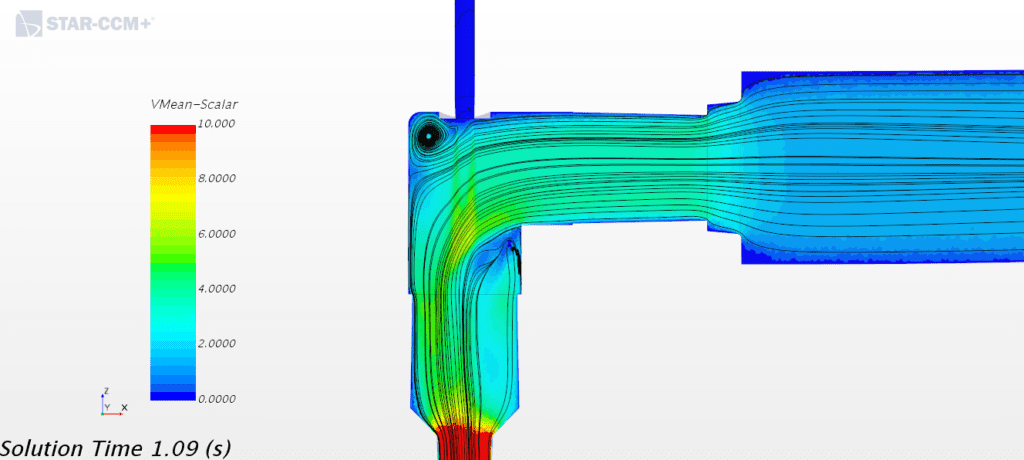

TotalSim was able to show that there is a flow separation zone where the air is unable to stay attached as it negotiates a 90 degree bend in the connector. Unfortunately the medication is injected into the system ahead of this separation zone and it along with the air from the ventilator is pushed to the outside of the 90 degree bend. The image below shows the streamlines of the flow that are biased to the outside of the 90 degree bend. This flow bias causes more of the drug particles to impinge on and adhere to the connector surface than desired instead of traveling down the ETT and into the lungs.

TotalSim provided a detailed analysis and suggestions on how the geometry could be changed to improve the medication delivery. The designers were then able to use the information to better understand the factors that influence the medication dispersion and to guide them on how the design can become more effective.

This kind of early prototype evaluation is always useful. The benefit of using CFD is that there is no need to create a physical prototype and test apparatus because it can all be completed in a virtual environment. This saves time and money as it is easier and quicker to create a digital prototype and iterate on variations than it is to create and test physical part after physical part. Additionally detailed CFD analysis gives insights that a simple experimental test will usually miss so you will often reach the desired result in fewer iterations.

CFD compliments or in many cases can replace the need for physical testing. Through our CFD consulting services we have helped many companies accelerate their design process.

Learn more about the ways TotalSim can help you overcome your aerodynamic challenges

*What is CFD?

Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses computer numerical analysis and data structures to analyze and solve problems that involve fluid flows, typically solved on large supercomputers. Fluid mechanics plays a significant role in the engineering process when developing new designs. Analyzing the aerodynamic and thermal qualities of a product using experimentation is a well-established approach however experimentation can be costly, limiting, time-consuming, and difficult to execute especially on a large scale. Progression of computing power has allowed the field of CFD to prosper acting as a complement to physical testing and in some cases replacing it. CFD is the science of predicting fluid flow, heat transfer, mass transfer, chemical reactions, and other flow properties by solving governing fluid flow equations using numerical methods. Across the industry, CFD is routinely used to drive product development, troubleshoot issues, study and optimize new designs and concepts, and map performance. CFD methods are heavily used across many disciplines with motorsports being a leading proponent.